Flexible endoscopes are highly delicate pieces of equipment and, unfortunately, vulnerable to damage. Normal wear and tear as well as physical trauma can lead to trouble. Regardless of the cause, the damaged endoscope has to be sent out for repair. Now you begin to ask, “How long will it take to fix?”

The answer to that depends on the extent of the damage. It could be a simple repair or there could be underlying problems you can’t see that complicate the repair. Until the scope has been thoroughly disassembled and inspected by a repair facility, it can be hard to tell where you stand.

What’ll empower you is to know the difference between what constitutes a “minor” repair and when a repair should be considered “major.” That’s what we’ll discuss in this special report.

Learning the Five Main Sections of Your Scope

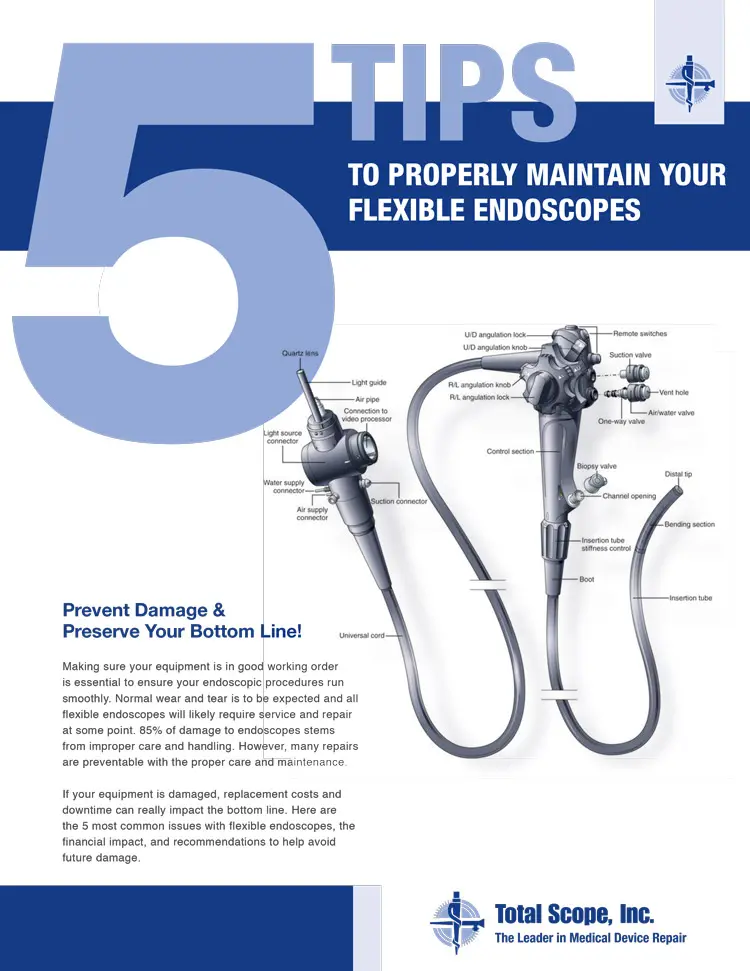

There are five different sections on the scope that need to be evaluated, and each section carries with it different repairs, both external and internal, ranging from minor to major. The five sections are:

- The light guide connector

- The universal cord

- The control handle

- The insertion tube

- The bending section

Minor repairs are defined as damage that can be repaired quickly and effectively, usually in a day. Major repairs are more complicated and time-consuming. They can take anywhere from 3 days to 3 weeks, though usually a week is sufficient. Fortunately, the vast majority of scope repairs can be classified as minor.

What Fluid Invasion Means for Your Scope

Understanding the function and anatomy of each section of the scope will help illustrate the differences between minor and major repairs. Before discussing these sections, it is important to realize there is one problem that can damage every section of your scope – fluid invasion. Fluid invasion is the most injurious mistake your scope can suffer.

That’s because fluid can enter any one area of the scope where a leak occurs and then migrate to other areas, causing damage to parts of the scope that may look fine externally. Fluid can be the main cause for tightness in the angulation dials, faulty or cloudy images, malfunctioning of the control buttons, and a number of other problems.

When fluid enters the scope, the repair becomes major because a scope cannot be fully evaluated until the fluid dries out. Under normal circumstances, the drying time for a fluid-invaded scope is anywhere from 48-72 hours, depending on the amount of fluid inside the scope. However, if you have fluid under the lens at the distal tip (where the bending section is), the drying time can range anywhere from seven to ten days; it’s difficult to dry out the fluid in a scope once it gets under the lens.

Once the fluid dries, the scope must be closely evaluated to see how much damage was done to it. Fluid invasion and the damage it causes will be discussed throughout each section of the scope as we break it down for you.

Section #1: The light guide connector

The light guide connector (LGC) is generally a very sturdy piece of equipment on the scope. It is the area of the scope that plugs into the processor to allow light to enter the scope during a procedure. The entire section of the light guide connector runs from the light post that plugs into the processor down to the control boot that provides support for the universal cord. However, quite a few components make up the LGC and each element is susceptible to damage from normal wear and tear or through physical trauma. A number of minor repairs can apply to the light guide connector. Understanding these minor repairs can provide insight as to how major repairs become required.

Let’s start with the components that protrude from the end of the light guide connector. The light post is the silver cylindrical piece that actually plugs into the processor. Though it is a solid piece of equipment, it can be damaged. The post itself can get dented or bent and cause trouble hooking it up to the processor. The post-repair/replacement is considered a minor repair if it does not have to be repaired in conjunction with other parts of the scope. The repair could be as simple as a dent removal or a replacement of the entire post.

However, an area that may get damaged within the post itself is the lens at the end of the post that allows light to enter the scope. Sometimes the light lens just needs a good cleaning, which is a minor repair. But if the lens gets damaged or cracked, fluid invasion can occur. And that could lead to major problems.

Located beneath the light post on most scopes is the air pipe. As with the light post, the air pipe is a strong piece of metal and quite durable. But the air pipe can get dented and it can also leak around the base that connects to the scope. In either case, as long as fluid hasn’t entered the scope, the air pipe repairs would be minor.

Other parts of the LGC that can be damaged are the suction port, the water bottle connector port and the S-cord connector. The suction tree looks like a miniature silver Christmas tree, and it is where the suction tube is hooked up during a procedure. The water bottle connector port is just what it sounds like. It’s where the water bottle attaches to the scope to introduce water into the scope. The S-cord connector acts as a ground so that the users and patients do not receive an electrical shock during a procedure. These units are metal and they hold up quite well during the life of a scope. If they need to be replaced, it is a minor repair. They can be replaced and sealed off, and this process does not take long to complete.

Sometimes the area around the ports can leak. These areas are normally sealed with epoxy. However, through normal wear and tear and physical trauma, the seal can be compromised and a leak can occur. Resealing these areas would fall into the minor category, barring any fluid invasion.

Seals around the electrical contacts (found on either side of the light guide connector, used to power the remote buttons) can leak as well. Again, as long fluid has not entered the scope, it’s a minor repair. If fluid enters the scope through the electrical contact area, there is a good chance that the electrical contact housing is damaged. If this occurs, what may have seemed to be a simple leak from an electrical contact is now compounded. Again, the major culprit is fluid invasion. Notice how fluid can have a “snowball effect” on repairs.

Let’s next discuss the electrical connector. There are quite a few prongs in this section; each one serves a specific function to ensure that the image on the screen looks right. As you place the coupler (a.k.a. the “pigtail”) onto the electrical connector, make sure not to jam it into position as this can cause the prongs to bend and break, requiring replacement. There is only one way for the coupler to be properly placed onto the electrical connector; any other way could cause damage to the prongs. If there is a problem, replacing the prongs is a major repair.

This area of the scope is a crucial section to keep in mind when it comes to properly leak-testing your scope. The water-resistant cap should always be placed on the scope immediately following a procedure and prior to leak testing. The cap serves as a shield to fluid invasion in this section. If a scope happens to be processed without the cap on properly, the scope will get fluid invasion. The same thing can happen if the cap is faulty. Most manufacturers recommend that you replace your water-resistant cap every 12-18 months (a little known fact) to prevent the normal wear and tear on the cap from becoming a problem. Make sure you track how many months a water cap has been in use.

Although rare, the entire light guide connector may need to be replaced if it has been exposed to an extraordinary amount of physical trauma. As mentioned previously, this section of the scope is very sturdy. But it is possible to have a fracture. If it can be repaired using epoxy, the repair would be minor. If the scope cannot be repaired using epoxy, the entire section would need to be rebuilt. If a rebuild is necessary, the repair will be major.

Section #2: The universal cord

There is more to the universal cord, which connects the light guide connector section to the control section, than meets the eye. As with the insertion tube, there are quite a few components concealed within the cord’s hollow tubing. Because of this, it is important to realize that damage to these unseen components may be the reason why what looks to be a minor repair turns out to be major.

The first and most common repair needed on a universal cord (i.e. the hollow tube that protects the components inside) is dent removal. Dents are caused through physical trauma and are a common complaint in the universal cord. If the universal cord only needs dent removal, it is considered a minor repair. The dents can be reshaped to ensure that the components are not being damaged beneath the universal cord. It is important to keep in mind that once a scope gets a dent, the dent can become weaker over time. Therefore the dent should receive attention when it is noticed, so as to not cause further damage to the components under the cord.

Another type of repair is strain repair.

PLEASE NOTE:

A strain repair is not recommended; however it can be done under certain circumstances (e.g. the customer simply must have the scope back quickly, the scope will be retired shortly, the budget is super tight, etc.). If a strain repair is performed, it is important to understand that it is a temporary fix. The nature of the strain repair will eventually cause weak spots on either side of the strain repair itself. Over time this will cause the insertion tube to buckle again.

A strain repair can be used when the universal cord has sustained trauma that has caused a buckle or a pinhole. These types of damages cannot be repaired by a simple dent removal; the universal cord needs to be supported. Strains in the universal cord can occur along the entire cord, but the most common areas are where the universal cord connects to the light guide connector and to the control handle. The damage usually occurs next to the control boots (the pieces of rubber that are designed to support the universal cord and insertion tubes to prevent them from buckling). Physical trauma is the usual cause of damage when a strain repair is needed. Strain repairs are considered minor repairs.

In the event that the cord is damaged beyond repair, it needs to be replaced. This can occur when the cord is dented severely, when the cord is cut or bent, or when the cord begins to peel after being exposed over time to certain types of cleaning agents. A universal cord replacement is considered a high-end major repair. The cord must be taken completely off of the scope, and that requires precision. The components inside the universal cord will also be exposed, making it a very delicate repair.

Two major components run through the universal cord – the suction channel and the fiber optic light bundle. The suction channel is a hollow tube that runs from the suction tree on the light guide connector down through the control handle. Since the suction channel is hollow, it can buckle and kink in the same way the universal cord does. If, during a procedure, the universal cord gets kinked 32cm from the light guide connector control boot, you repair facility may also find that the suction channel is impeded at exactly 32cm from the light guide connector as well.

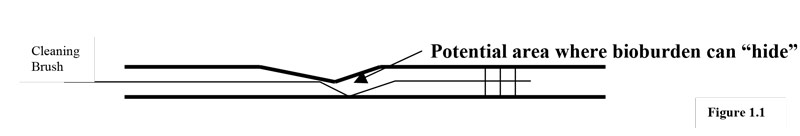

An impede, or blockage, in the channel can be measured on a scale of 1 to 10. A level 1 won’t disrupt the function of the suction channel too much. However, once a suction channel is impeded, it cannot go back to its original circumference. As instrumentation and the cleaning brush are used in the impeded channel, the impede level will eventually increase to a 3, then a five, and so on, with a level 10 being a hole in the channel. Also, an impede in the channel can lead to improper disinfection of a scope. As the impede grows, it becomes increasingly difficult for the cleaning brush to access the spot behind the impede. Bioburden can remain in this “hidden spot.” Figure 1.1 illustrates how an impede can potentially conceal bioburden near the impeded channel.

As a result, any impede in the suction channel is a cause for a suction channel replacement, thus becoming a major repair. The suction channel replacement is a time-consuming repair because the universal cord needs to be replaced in order to replace the channel. The new channel needs to be connected correctly to the light guide connector and the control handle to ensure that the suction works properly during a procedure.

As with the suction channel, the fiber optic light bundle can experience damage caused by physical trauma. The light bundle is a series of strands of glass bundled together. These bands transport light from one end of the scope to the other, allowing for lighted vision during a procedure. These strands of glass can get shattered, and depending on the amount of strands that are damaged, the light can get quite dim or go out completely. Some scopes have two fiber-optic light bundles (mostly larger diameter scopes); other scopes (small diameter) only have one.

These lights work on a percentage scale. If a light bundle doesn’t have any damage, it is considered to be working at 100%. If a light bundle is working at 90%, the end-user may not notice a difference in the light performance. However, if the light is working at 50% or less, the light bundle may need to be replaced. In this case, the repair would be major.

The fiber optic light bundle runs through the entire length of the scope, therefore the universal cord and the insertion tube would need to be removed to replace the damaged light bundle. This repair requires precision due to the nature of the lights. Since they are glass, they can break rather easily, so replacing the lights is a delicate and tedious task. Keeping in mind that the light bundle is made of glass, it is especially prone to damage from fluid invasion. As fluid is dried out of the scope, the fiber optic light bundle becomes brittle. The more often a scope gets fluid, the more likely that the scope will need a light bundle replacement because each time the scope dries out, the light bundle becomes more brittle. Eventually, as the bundle gets weaker, the physical trauma needed to damage the light bundle considerably decreases, rendering the scope increasingly liable to need replacement, a major repair.

Section #3: The control handle

The control handle on a flexible endoscope is very susceptible to damage for a number of reasons. This particular section of the scope gets an enormous amount of use because it is here that the doctors manipulate the scope while in a procedure. All of the functions of the scope (angulation, taking pictures, running instrumentation down the forcep channel, etc.) take place in this section. The entire section of the control handle runs from the control boot that supports the universal cord down to the control boot that supports the insertion tube. As with the light guide connector, the control handle consists of many parts that will wear down over time or that can be damaged by physical trauma.

The control handle itself is a very sturdy piece of equipment. The handle is made of a durable plastic and it holds up well during the life of the scope. However, if the handle is fractured or shattered, it will need to be replaced. This type of repair would be considered major because there are many components on the control handle that need to work correctly after the handle is replaced.

Two angulation dials on the control handle of most flexible endoscopes allow a user to manipulate the scope during a procedure. They are susceptible to damage because they are used considerably during procedures. Angulation dials can suffer a broad range of injury, most of which would be considered minor.

The first and most common repair is an angulation adjustment. Over time, and through normal wear and tear, the angulation on a scope needs to be adjusted. The user may notice that in any

given direction the scope does not angulate as well as it should. When this occurs, the repair for the angulation would be minor, as long as the repair was isolated.

The angulation dials themselves can leak and crack (they’re made of plastic). If they crack, they need to be replaced. Again, this would be a minor repair barring any fluid invasion in the scope. Also, if the dials are leaking (which is a common occurrence due to normal wear and tear), they can be repaired rather easily.

Next to the angulation dials are freeze knobs that allow a user to lock the bending section in place during a procedure. Similar to angulation dials, the freeze knobs can be repaired or replaced as needed, which would be a minor repair. The freeze knobs can get loose to the point that the move on their own. If this happens, you need to repair or replace them. If they move on their own, they can lock in place without the user knowing they are locked. If the user then angulates the scope with the locks engaged, it will be considerably harder to manipulate the scope.

When angulated, a scope’s angulation cables are being used. If stressed, these cables can snap anywhere from the control handle down to the bending section. If the angulation cables snap, the scope becomes useless because you can’t maneuver it during a procedure. Overangulating the scope is one of the most common reasons why cables snap. The required repair at this point would be a cable and cannula replacement (the cannula guides and protects the cables from damage through the insertion tube). This is an extensive, and therefore major, repair. The cables need to be properly aligned inside the scope to ensure that the angulation will work properly when fixed.

Another common reason for a cable and cannula replacement is if the cannula gets damaged. As mentioned, the cannula serves as protection to the cables. If the cannula is impeded, it hinders cable movement, causing trouble angulating. Also, the cables will rub against the cannula, causing them to fray and eventually snap.

A problem that appears similar to cable snapping is angulation post repair. But it is far less extensive than a cable replacement. When an angulation post slips inside of the control body, it looks as though a cable has snapped. The user will not be able to angulate much, if at all, in the direction that the post has slipped (right, left, up, or down). The repair needed to fix the post takes place in the control body, so an angulation post repair is considered minor.

The next section on the control body to discuss is the top of the control handle where the buttons sit. The buttons are manipulated to take pictures. These buttons are made of rubber. Cuts, tears, and pinholes in the buttons are not uncommon. Repairing or replacing the buttons is considered a minor repair.

The housing located on the control handle is known as the control switch housing and it controls the button functions (freezing of pictures, changing frames, taking pictures, and so on). A number of problems indicate the control housing needs to be replaced or repaired: the buttons may not respond at all when pressed, the scope may be taking pictures or freezing on its own, or the correct response occurs only intermittently. Also, the housing can simply wear out over time or be damaged via fluid invasion. In these instances, the control housing would need to be replaced. Depending on the extent of the damage, repairs to the control switch housing can range from minor to major. If the housing needs to be replaced, it’s major.

The final sections to be noted on the control handle are the ports. Depending on the type of scope (gastroscope, bronchoscope, colonoscope, etc.) there are up to four ports on the control handle (suction port, air/water port, biopsy port or auxiliary water port). Keep in mind that each port is sealed, but they can leak over time or through physical trauma. In the event that one of the ports leak, the repair would be minor, unless the scope was fluid invaded.

The suction port and the air/water port are more prone to damage than the other ports due to the buttons and the cleaning brush being used on these ports. A damaged suction port can cause poor insuflation and the air/water port may leak as a result of the ports wearing down. As with any component of the scope, it is important to understand that minor damage to these parts can lead to major repairs.

ERCP scopes (a.k.a. duodenoscopes) have an additional component on the control handle – the elevator knob. The elevator knob is used to manipulate the elevator wire, which is connected to the elevator, during a procedure (more on these 2 items later). The elevator knob can leak or loosen just as angulation knobs can. In either case, the knob would require a repair or a replacement. This is a minor repair, since it would be done on the control handle.

An elevator pin is located in the control body as well. This pin connects the elevator wire to linkage that connects directly to the elevator knob. The pin can break from normal wear and tear. Replacing the pin is a minor repair.

Section #4: The insertion tube

The insertion tube mirrors the universal cord in many ways. Both the universal cord and the insertion tube are hollow, and they both protect internal components from damage while providing flexibility in a procedure. However, the insertion tube, because of the function it serves in a procedure, is much more prone to damage than the universal cord. Some of the minor repairs that can be done on the insertion tube are consistent with that of the universal cord: it could require dent removals and cleaning and flushing of the channel. These repairs are minor ones because they are external and require only slight adjustments to the scope. NOTE: A strain repair could also be done on the insertion tube, but again, this type of repair is not recommended.

Replacing the insertion tube, as with the universal cord, falls in the major category because the damaged tube must be removed from the scope and the new one placed correctly to ensure that the scope functions properly.

Another similarity that the universal cord and the insertion tube share is the light bundle. The light bundle can be damaged by both physical trauma and fluid invasion in the insertion tube, much in the same way as it is damaged in the universal cord. The point here is that external damage to the insertion tube can cause quite a bit of damage under the tube; thus what seems to be a minor repair could turn out to be a major one.

The forcep channel (a.k.a. biopsy channel) is a hollow tube that runs through the insertion tube, similar to the way the suction channel runs through the universal cord. It can get impeded and the impede can wear down over time, just like a suction channel. It, too, is considered a major repair due to the intricacies involved in the repair process.

The biggest difference between the forcep channel and the suction channel is that biopsy instrumentation runs through the forcep channel, rendering it more susceptible to damage than the suction channel. Not only can the cleaning brush wear the channel down over time (potentially causing improper disinfection, see figure 1.1), but sometimes sharp instruments that run through the forcep channel can open up while in the channel, causing immediate and extensive damage. When this occurs, the repair will be major. It is not uncommon for this to happen.

As mentioned in the control handle section, the angulation cable and cannula run throughout the insertion tube. The cable and cannula can experience damage from wear and tear or physical trauma. Sometimes the cables snap in the insertion tube. When this occurs, the cables and cannula cannot be repaired without fully disassembling the scope. This repair is major and critical, since it involves the angulation of the scope.

All video scopes have video wires that run through the insertion tube as well. These wires can get damaged from physical trauma and especially from fluid invasion. Repair of these wires would be considered major.

The last component within the insertion tube to mention is an image bundle. Prior to video chips, flexible endoscopes all used image bundles to directly view inside a patient during a procedure. The image bundle is similar to the fiber optic lights. Instead of carrying light through the scope, the image bundle allows a user to view through the scope. The problems that can occur with the image bundle mirror the damage that occurs with the light bundle. The image bundle is a series of glass fibers that can break or shatter from physical trauma or fluid invasion. As the damage occurs, the user will begin to see “pepper dots” or black specs on the image. These dots are broken fibers. As the fibers break, the image becomes obscured and eventually the image bundle will need to be replaced. The benchmark to decide whether or not a scope needs a new image bundle is 35 or more broken fibers. Keep in mind that a new image bundle is basically always manufactured with broken fibers, therefore a new image bundle that has 3 or less broken fibers in the field of view is acceptable by industry standards.

Replacing the image bundle is a major repair because the entire bundle must be secured properly and the bundle itself is fragile. Because of advances in technology, the “direct view” scopes are used less frequently now. However, there are still a considerable number of bronchoscopes in use that have image bundles.

An ERCP scope has some other areas beneath the insertion tube to consider regarding major and minor repairs. While ERCP scopes have the same components beneath the insertion tube as other scopes, they also contain an elevator wire and an elevator channel. The nature of ERCP procedures requires the use of instrumentation that is guided by the elevator located at the distal tip. The elevator wire controls the elevator during the procedure. This wire can snap or fray in the same way that angulation cables snap, that is from fraying or external trauma. If a cable snaps, you can’t manipulate the elevator during a procedure, and the scope is useless. Replacing the elevator wire is a major repair, since it requires that the scope be fully disassembled.

The elevator channel can be compared to an angulation cannula in that it acts as a protective, hollow guide for the elevator wire. The channel can get damaged from external trauma (this usually occurs when the insertion tube receives considerable damage). When the elevator channel is damaged, it can hinder the function of the elevator wire, thus causing the elevator to function improperly. Repairing or replacing the elevator channel is a major repair, since the scope would have to be fully disassembled.

Section #5: The bending section

The bending section may be the smallest area on the scope, but it has the highest risk of damage because of its function in a procedure. The bending section runs from the epoxy band that secures the bending rubber in place (next to the insertion tube) down to the distal cap (a.k.a. the distal tip). This section can be broken down into the bending rubber, the bending mesh, the angulation collar and the distal cap.

The bending rubber is by far the most common component of an endoscope that needs repair. It is the thinnest part of the scope because the bending section needs to be manipulated once inside a patient. The bending rubber is simply a material that is secured by two epoxy bands on either side. When the scope is angulated, the bending rubber can get stretched. It can experience many types of damage: pinholes, cuts, looseness and aging are the most common reasons why a bending rubber needs to be replaced. In each case, the repair would be considered minor as long as there wasn’t any additional trauma under the bending rubber (in the bending mesh).

Please remember that the vulnerability of the bending rubber also makes it very susceptible to fluid invasion. Once fluid enters this section of the scope, a considerable amount of damage can occur since the bending section contains all the components of the insertion tube (angulation cables, forcep channel, light bundle, video wires), as well as the video chip.

The bending mesh can best be described as a “screen” that protects many components of the scope. The mesh is very strong while being flexible enough to allow manipulation during a procedure. Through wear and tear and physical trauma, this section can experience holes, cuts, and other forms of damage. It can also rub against the forcep channel or the angulation cables when it is damaged, thus injuring those areas as well. Replacing this section requires a considerable amount of work, making it a major repair. The mesh must be repaired correctly to allow the other areas of the scope to function appropriately beneath it.

The angulation collar is located beneath the bending mesh. The angulation collar can be described as a “chain-link armor” (comprised literally of links of metal). This section allows the bending section to “flex” during a procedure. It is susceptible to damage and it can also damage components that run through it (namely, the forcep channel, angulation cables and cannula, and video wires). Repairing or replacing the angulation collar is considered a major repair.

The distal cap is the final area that we will discuss. The cap itself is a piece of plastic and can be damaged in a number of ways, including scratches, chips, cuts and cracks. Fortunately, the cap is easy to replace and this type of repair would be considered minor.

On the top of the cap sit a few components. The first part that protrudes out of the scope is the air/water nozzle. The air/water nozzle helps clean the lens during a procedure. It can experience physical trauma, clogging due to bioburden, and collapse due to damage which will cause poor air and water flow. These problems mean the nozzle would need to be replaced. This is a minor repair, although with a clogged nozzle, the air/water channel needs to be cleaned and flushed to remove any lingering bioburden.

The other areas on the distal cap that can get damaged are the light lenses and the objective lens. These lenses can experience the same type of damage as the light post lens that was discussed in the light guide connector section. The lenses can crack and leak, causing fluid invasion. In the event that the lenses crack, even if the scope doesn’t have fluid, the repairs on these lenses would be major.

The distal cap of an ERCP scope is a bit different from the caps used on other scopes. The nature of an ERCP requires a different view during the procedure, so its distal cap looks different. The ERCP scope cap has a rounded top and the image lens, air/water channel, and the light lens are all found on the side of the cap. This cap is made of plastic and can experience the same type of damage as a regular cap. If the cap is cracked or severely scratched, it needs to be replaced. This would be considered a minor repair, barring any other damage to the scope.

The ERCP distal cap also has a very important component on it that is unique to ERCP scopes. This component is the elevator. The elevator serves a very distinct function during a procedure, as it helps a doctor precisely guide instrumentation through the scope and into the patient during a procedure. Problems with the elevator are mainly found in the control body and in the insertion tube. However, the elevator opening at the distal tip can sometimes clog from bioburden. In this case, the port would need to be cleaned. This is considered a minor repair.

The video chip is one of the most important components of a flexible endoscope. The chip allows users to see a crisp, clean image during a procedure. The chip sits in a carriage located in the distal tip and can be damaged in a number of ways. And if fluid invades it, the chip can short circuit, causing many different effects – the image could have lines running through it, different hues could be seen in the image (red, blue, green, etc.) or the image could become blurry or distorted. If the video chip can be repaired, the wires need to be restored correctly to ensure that the image will again be clear. This repair is delicate and time consuming; therefore it falls into the major repair category. If it has to be replaced, well that’s a major repair, too. Unfortunately, because of the complexity of the video chip, basically any repair to it is a major one.

There you have it: a brief rundown of scope anatomy and what makes a repair hard or easy. Basically, the more damage a scope receives internally, the more likely that the repair will be major, especially if fluid has entered the scope. Also remember that external trauma to a scope may cause internal problems that cannot be seen.

There is more to flexible scope repair than meets the eye in most cases. By understanding the functions and components of your scope you’ll be better able to work with your scope repair company and know what they’re doing and why. After all, it’s your scope, right?

If you’d like more information about endoscope maintenance and repair, you’re welcome to contact the experts at Total Scope, Inc. Call us at 800-471-2255.

Click here to learn the benefits of using Total Scope for your endoscopy repairs.

FREE SHIPPING Anywhere in the Country for Repairs

FREE SHIPPING Anywhere in the Country for Repairs