Taking time to properly care for your endoscopes after each use is crucial to their longevity.

Taking time to properly care for your endoscopes after each use is crucial to their longevity.

Neglecting your endoscopes can result in hefty repair costs—which are easily preventable if you take care of them properly. If you do take good care of your endoscopes, your procedures will run more efficiently, saving your department and patients time and money. To learn about the different types of damage your scopes can incur, check out this post about hard vs. easy scope repairs.

Reprocessing your flexible endoscope is a continuum; all steps are done one after the other and they must be done in a meticulous manner. If you follow these 7 easy steps, you can expect to keep your endoscope in good condition.

7 Flexible Endoscope Reprocessing Steps

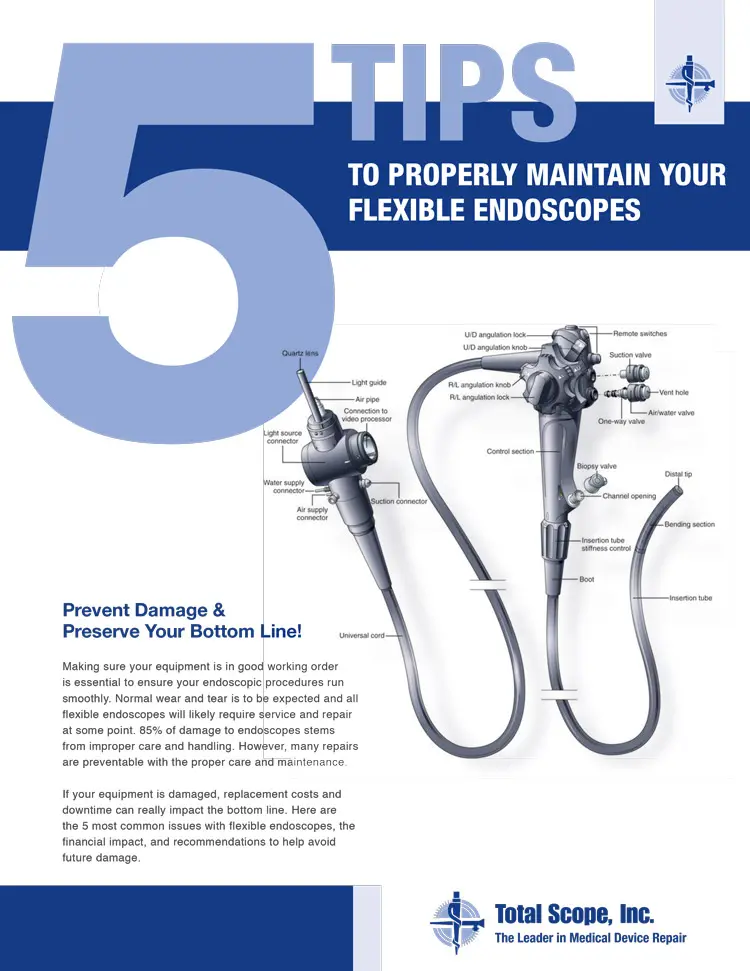

- Pre-Clean Your Scope. Reprocessing begins in the procedure room. Pre-cleaning helps prevent the formation of any biofilm, so it’s critical to start the cleaning process immediately after removing the insertion tube from the patient. If the remaining soil isn’t removed promptly, it has the opportunity to dry which risks complete decontamination. To pre-clean, wipe the insertion tube, clear the air/water channels and soak in detergent solution. Note: make sure to remove all detachable components (air/water valve, suction valve, biopsy port cap) & soak in solution separately.

- Perform a Leak-Test. Leak tests allow you to detect any damage to the external surface of the scope, as well as the internal channels. If you don’t perform a leak test and the scope does have internal damage, this can lead to inadequate disinfection and even further damage to the endoscope. It is essential to perform a leak test after your scope has been pre-cleaned. For tips on performing a productive leak test, check out this past post.

- Manually Brush & Flush. Manually cleaning the scope is a critical step in the disinfection process. When performing this step, the scope must completely immerse in the cleaner. During this step, it’s time to put the previously detached components into the container to scrub them. When cleaning the exterior, use a soft brush or a lint free cloth. Make sure to thoroughly brush and flush any residue that may be lingering in the channels and ports, since residual matter can reduce the effectiveness of the sterilization process. Let teh scope and components soak in detergent for the time frame recommended in the manufacturer’s manual.

- Rinse & Dry. Thoroughly rinse the detergent from the endoscope with clean water. Next, use a lint-free cloth to wipe down the endoscope before drying the inside of the scope by pushing forced air through all the channels. The scope must be completely dry before moving onto the high-level disinfection process.

- Disinfect. According to the manufacturer, follow reprocessing instructions for proper sterilization or high-level disinfection (HLD). Carefully review what equipment or chemicals are to be used so you can perform the most effective disinfection method. Once immersed in the solution, inject the solution through the channels and soak the scope for the recommended length of time. After soaking, use forced air to rid of any remaining disinfectant. Transfer the scope and components into a container of clean water and then remove scope & place onto a sterile towel. Dry with a lint-free cloth.

- Flush with Alcohol. Flushing the scope with alcohol promotes drying of the channels to prevent any bacterial growth. Using 70% Ethyl or Isopropyl alcohol, aspirate through the channels by using the suction device. Then use forced air to dry out the remaining alcohol. Finally, use an alcohol-soaked, lint free cloth to wipe the exterior of the scope followed by drying ports with a cotton swab.

- Store & Don’t Forget to Document! When storing your scope, hang it in an uncoiled, vertical position to facilitate drying and prevent recontamination. Make sure there is enough room between devices so you can avoid damage caused by contact. For quality assurance purposes, it is highly recommended to maintain documentation throughout the entire process. Having this on record can be very helpful if there is ever a circumstance that requires you to backtrack, whether it be due to improper disinfection or a recall. You can find our best tips on documenting repairs to your scopes here.

To learn more about how to extend the life of your scope with proper maintenance, check out this post as well as our endoscope preventative maintenance guide. Contact Total Scope to for any endoscope repairs.

FREE SHIPPING Anywhere in the Country for Repairs

FREE SHIPPING Anywhere in the Country for Repairs