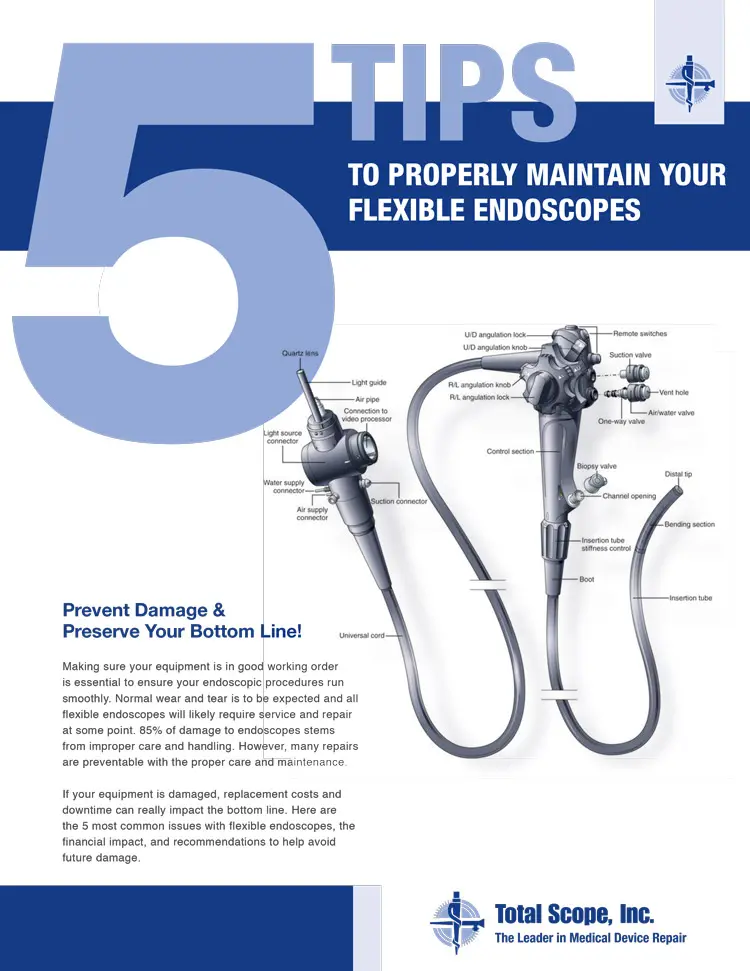

Total Scope Inc. is a premier worldwide endoscope repair facility servicing all major endoscope and surgical camera brands. Total Scope frequently accepts repair orders for angulation system repairs. The angulation system includes a series of control cables connected to a gear/pulley system in the control body. The cables are manipulated through a series of metal wiring that runs throughout the insertion tube and into the bending section. When the mental wiring does not move together properly, abnormal bending of the angles and performance specifications outside of OEM standards occur. For a quote on a repair contact us or call (800) 471-2255. Follow these tips to prevent these types of repairs in the future.

Total Scope Inc. is a premier worldwide endoscope repair facility servicing all major endoscope and surgical camera brands. Total Scope frequently accepts repair orders for angulation system repairs. The angulation system includes a series of control cables connected to a gear/pulley system in the control body. The cables are manipulated through a series of metal wiring that runs throughout the insertion tube and into the bending section. When the mental wiring does not move together properly, abnormal bending of the angles and performance specifications outside of OEM standards occur. For a quote on a repair contact us or call (800) 471-2255. Follow these tips to prevent these types of repairs in the future.

Common Causes:

- Overtension or tightly coiling.

- Fluid invasion causes internal components to bind together.

- Compressed, buckled, soft, or weak insertion tubes can make internal components tight and put stress on cables/bending sections

- The condition of the forcep channel may cause issues. This includes the age, length and stiffness.

- Kinked or damaged coil pipes can cause an angulation wire to fray or break.

Prevention Methods:

- Avoid extended periods of coiling and/or sharply bending the insertion tube. This increases the friction on the cables and puts a great amount of stress on the solder joints.

- Avoid extreme twisting and torque on the insertion tube during procedure.

- Use sinks or soak baths large enough, where the scope does not have to be over-coiled for long periods of time.

- Use bite blocks to prevent damage to the bending section.

- Avoid stacking endoscopes at any period of time.

- Scopes should be stored to allow insertion tubes to hang straight and untangled in the unlocked position.

- Leak test the scope thoroughly after each procedure. Any fluid invasion can cause corrosion and binding with internal components.

FREE SHIPPING Anywhere in the Country for Repairs

FREE SHIPPING Anywhere in the Country for Repairs